Ten Steps to Kanban Design

How to Design a Kanban System

Simple Operation, Sophisticated Design

While kanban systems are quite simple in concept and operation, their design may require significant analysis. In the most favorable situations, experienced guesswork may be adequate for a design. In more difficult situations, guesswork often seems to rule out kanban when a more thorough approach would make it feasible. An effective design requires insight into demand patterns at the downstream workcenter, capacity analysis at the upstream workcenter, downstream scheduling practices, setup practices, material handling methods and lot sizing.

From the earliest publications on lean techniques such as Monden and Hall, many authors have described kanban systems in detail and many researchers have explored kanban operations. However, few have explored the intellectual process required to design these systems or proposed a design procedure. This paper presents such a 10-step process in a structured and systematic approach that ensures a successful kanban design.

1. Kanban & Other Production Control Methods

What is Production Control?

At the most fundamental level, Production Control is simply the coordination of two sequential operations. Of course, it gets more complex when considering capacity, staffing, lead time, routings and many other factors. One way to state Ashby’s law is that the controlling system must be at least as complex as the system controlled. In Lean Operations, workflow is simple and straightforward and the production control system should match this relative simplicity.

A Hierarchy of Production Control

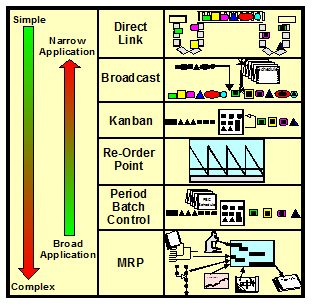

Production Control systems fall into several categories based on their fundamental operational principles. Figure 1 shows these categories ordered from the simplest to the most complex.

In Direct Link, the upstream and downstream workcenters are physically connected. The connection may be a conveyor, as shown, or the workcenters may be adjacent. In either situation, the downstream workcenter simply works on whatever product emerges from the upstream and does so when it emerges.

A Broadcast system is often used when major subassemblies are used on a final assembly line. The subassembly and main assemblies are often custom-made and not interchangeable. In this system, a master schedule is prepared that determines the sequence of and timing of final assembly.

Kanban uses a small stock of product located between the upstream and downstream workcenters. A signaling system informs the upstream workcenter as each withdrawal is made. This allows the workcenter to schedule a replenishment along with any other items it must produce.

Re-Order Point (ROP) systems maintain a stock of each item that may be required at the downstream workcenter. This downstream workcenter pulls stock as required. When stock levels fall to a designated “minimum” or “Re-Order” quantity, a purchase order or other signal is sent to the upstream workcenter for replenishment to the maximum quantity. While some features of ROP resemble Kanban, ROP normally works with larger lot sizes and much longer lead times. Moreover, the replenishment signal is initiated when the stock is at the lowest allowable point, not when it is withdrawn.

MRP/ERP systems from a vast amount of data concerning process, work times, inventory at every stage, suppliers, lead times, sales forecasts and sales orders. With all this complexity, an MRP/ERP system can, in theory, schedule almost every production situation. Practice, however, presents a multitude of problems. The cost, complexity and risk associated with it make MRP the last resort.

Generally, the most complex systems have the broadest application. Broadcast and Direct Link, for example are only feasible under certain very special conditions whereas modern MRP systems can be used in nearly every situation. But the simpler systems, properly applied, work better in many ways. Kanban is about midway in terms of simplicity and range of application.

Here, in this short paper, we focus on kanban systems. However, a given facility may use several or all of the various methods.

2. The Essence of Kanban

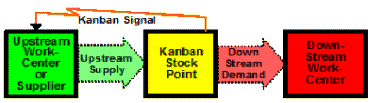

Figure 2 The Essence of Kanban

Kanban takes place between two workcenters; an upstream supplier and a downstream user. It applies to a single part or SKU. Between the workcenters, a Stockpoint holds a (relatively) small stock. A signal immediately notifies the upstream workcenter of changes in stock status. Therefore we can define a Kanban system as one that has:

- 1. Small Stock Available

- 2. Withdrawal Signal With Immediate Feedback

- 3. Fast Replenishment, Small Quantities

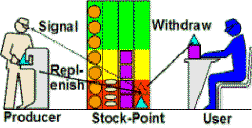

Figure 2 illustrates with a block diagram and simple example. In this example the operator at the upstream workcenter simply watches the Stockpoint and, with the aid of color codes, determines what he produces next. This is a simple, visual signal that is highly effective. There are many other types of signals as well.

The Rules of Kanban

Kanban requires a set of rules and procedures and the discipline to carry them out. A simple system as in such as in Figure 2 needs only two basic rules:

- No production without a kanban signal.

- Do not arbitrarily change authorized stock levels.

More complex systems using containers or cards may have some additional rules.

For the system in Figure 2, the “User” or downstream workcenter simply builds what its customer needs immediately and removes the required items from the Stockpoint. The “Producer” or upstream workcenter observes the Stockpoint and decides which items to build based on the stock level. Colored zones make the stock status more obvious:

- Red zone means “make this part NOW.”

- Yellow means “be prepared to make this part soon.”

- Green means “you may build this part if convenient but only up to the maximum level.”

■ ■ ■ ■ ■ ■ ■