Mixed Model Summary

Making The Impossible Possible

In A Nutshell

In A Nutshell

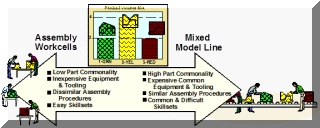

There are many roadblocks to mixed model production lines and assembly cells. Here are some of the roadblocks and ways to get around them.

The principle of Mixed Model Production is simple enough. Designing the process and system is often more difficult. In this page we explore common roadblocks and describe some techniques to eliminate them.

Mixed Model Assembly Lines

| Problem | Description | Solutions |

| Work Balance | When different models have different work content, operations must be flexible enough to deal with the product mix. |

|

| Part Availability | For a mixed model assembly line to function, every part for every product must be immediately available. |

|

| Tool Availability | Tools and special fixtures must be readily available. (This is seldom a problem when the product is small. It may be a problem with large products such as refrigerators or vehicles.) |

|

| Fabrication Setup Reduction | Dedicated fabrication equipment is not always available. Long, expensive and/or inconsistent changeovers force large batches and high inventory between fabrication and the mixed model line. |

|

Dedicated Assembly Cells

| Problem | Description | Solutions |

| Demand Variability | Variation in demand for each dedicated cell may be larger than the variation for a single line. (Peaks and valleys of demand often cancel when combined.) |

|

| Cell Design | Workcells appear simple and this is especially true for assembly cells. In reality they are complex and sometimes sensitive socio-bio-technical systems. |

Integrated Cells

| Problem | Description | Solutions |

| Process Incompatibility | This usually involves processes that must be isolated for environmental reasons (Dust, Dirt, Chemicals or Noise). |

|

| Process Scale | Large-scale fabrication processes have too much capacity for a single assembly cell. |

|

| Special Skills | Certain tasks require extensive skills, experience and/or training but do not require a full-time operator for each cell. |

|

Reference:

LEE, QUARTERMAN, Mixed Model Production--A forgotten Aspect of Lean, IISE Annual Conference Proceedings, Philadelphia, PA, USA,2017

■ ■ ■ ■ ■ ■ ■