Enabling Mixed Model Lines

Here are The Challenges

Production Smoothing

Production smoothing in the upstream processes is normally the result and an objective of Mixed Model Assembly and Mixed Model Assembly can cope with considerable variation in customer demand. However, the smoothing of demand downstream of assembly can help a mixed model line run better and further improve the demand variation of the upstream processes. It is always beneficial to examine downstream demand and find ways to reduce day-to-day variation. Smoothing customer may be remarkably simple and easy.

One pharmaceutical manufacturer experienced frequent short-term demand for one or another product. Investigation revealed that this was the result of a sales promotion policy in which certain items were put on sale to veterinarians across the entire country on a regular basis. The solution was simply to rotate the sale items among different regions.

Material Staging

Every part for every model must be staged immediately adjacent to a Mixed Model line. This may be problematic when the product has many parts and there are many models. However, the need for each part is less when running mixed models as opposed to a batched line.

A kanban system is often ideal for this situation. A small stock is carried at the line and is replenished from an upstream workcenter, a warehouse or directly from an outside supplier. It all depends on usage, demand patterns and the physical size of the components.

Inline Equipment

Many assembly lines have integrated equipment for forming, flipping, assembling, wrapping or testing, as in figure 13. If such equipment requires long changeovers from one product to the next, the changeover may prevent mixed model assembly. Every effort should be made to reduce the changeover time of such equipment using SMED techniques.

Work Balance

Henry Ford's highly balanced assembly line has been the dominant production model for almost 80 years. However, such lines have significant problems. Most short-cycle lines that appear to be balanced actually have significant balance losses that exceed 20%. Production lines can have perfect average or static balance and yet be highly unbalanced from cycle-to-cycle (dynamic balance). Understanding these factors is important when selecting balance methods.

Inherent Balance

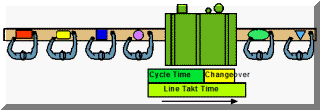

Inherent balance attempts to provide each workstation with precisely the same amount of work. With high-volume assembly lines, this may be achievable, to some degree. Manual assembly is flexible because people are flexible. Analysts divide the work into minute tasks. They reassign these tasks to work stations such that each station has the same cycle time. Balancing mechanized or automated production lines with this method is more difficult since it is rarely possible to find equipment with identical cycle times. Figure 13 shows inherent equipment balance.

Perhaps the most formidable problem of inherent balance comes from variation from one cycle to the next. The work times developed by traditional time study show average deterministic times of great accuracy. In reality, these times may vary significantly from one cycle to the next. The time at a given station is, in fact, a distribution. When the time on a station is longer than the average, it slows the entire line. When the time on a given station on a particular cycle is less than average, it cannot speed up the line. Thus, the real performance is less than the average cycle times indicate. The more stations, the more this variation affects performance.

Surplus People Balance

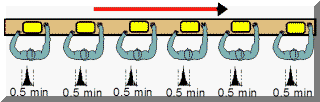

Surplus balance means that we simply ignore the imbalance and allow some people to have less work. While surplus capacity is a reasonable method for balancing machines, particularly inexpensive machines, it rarely is acceptable for balancing people. When customer delivery is critical and customer demand irregular, surplus capacity may be used to ensure fast delivery. In figure 6, one of the six operators requires more work than any of the others. This is the bottleneck. Other operators have surplus capacity.

Queuing Balance

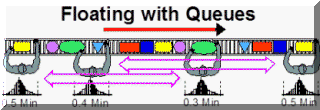

When operators have permanent stations in a cell or line, queuing between them compensates for cycle-to-cycle variation. Floating-fixture assembly lines work on this principle. If the average work times differ, queuing alone is insufficient. Queuing alone balances the short-term or dynamic variations but it will not compensate for longer-term static variation. Figure 7 shows how these small queues buffer short-term variation. The size of the queues relates to the amount of variation. From Theory of Constraints, we know that by observing the queues, we can see which operators are most imbalanced.

Floating Balance

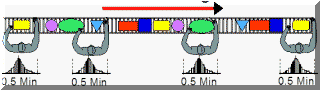

Floating balance, usually combined with queuing, is frequently a good method for balancing people. Here, operators monitor the queues to determine which stations are working ahead and which are falling behind. Operators move to the stations that are falling behind and assist until that station is caught up. This requires that stations allow for multiple operators when necessary. Figure 8 illustrates.

■ ■ ■ ■ ■ ■ ■