Strategos Lean Training

Targeted—Practical—Engaging

A Personal Message

A Grand Adventure

A Grand Adventure

We try to make learning an adventure. A voyage of discovery where individuals and teams find new talents, skills, pride and satisfaction.

"Adventure" and "discovery" imply risk—unknowns. This is why we explore real problems and situations from the participants' own workplace. Nobody knows exactly what will emerge. What does emerge is nearly always stimulating and full of lessons. Email or call me anytime—no obligation for a phone call.

Quarterman Lee, 816-931-1414

Our Programs

Targeted—Practical—Engaging

Give your people the skills to solve their own problems. We provide training that addresses the specific situations they face every day. Often with a case study from your own facility. The result is a trained cadre of employees and an actual:

|

|

Strategos programs employ proven principles of Adult Learning. They are full of videos, dialogue, exercises and experiential learning. Instructional methods alternate frequently to maintain interest and address the learning modes of individual participants.

Our "Learning Team" approach engages participants, increases discussion and allows for large overall sessions (50 or more). Go To Standard Program Listing >>

Program Formats

Standard Topics

Economic & Effective

Standard Programs

Cost-Effective & Convenient Training for Your Team

Our standard programs are effective and economic for pre-defined topics. They have been refined over many presentations.

These programs use Team Learning and can accommodate large sessions of up to 50+ participants while enhancing the learning experience. We can customize most programs to fit your team's needs.

Customized Topics

Tailor Made for Your Team

Customized Programs

Tailor Made for Your Team

We can design programs around your firm's terminology, production system philosophy, specific needs or technologies. When based upon our standard programs, they are cost-effective.

If you are having difficulty finding the program that addresses the specific topics you require, call us to discuss the possibilities. (816-931-1414)

Kaizen & Action Learning

Learn & Do Concurrently

Kaizen Events/Action Learning

Learn & Do Simultaneously

We can incorporate mini-kaizen events in most of our training programs. Here, teams of participants apply their new skills and knowledge to specific, practical problems from their own workplace. Under the guidance of an experienced Strategos facilitator and with new techniques freshly in mind, these teams show remarkable success in a very short time.

These events might range from a 1-day 5S Kaizen to a one-week workcell design. We have used kaizen events for Value Stream Mapping Projects and also for plant layout projects where the actual implementation comes at a later date.

If you think that such an approach would be useful in your situation, call us to discuss it and plan an initial scope.

Training Kits

Conduct Your Own Training

Training Kits

Conduct Your Own Training

Training Kits allow firms to conduct high-quality training with their own instructors. They are effective when basic subjects are taught to a large number of employees. They are also effective for periodic training of new employees.

These kits include a screen presentation, workbook, instructor manual and other materials required to conduct multiple class sessions. Most of our kits are supplied by Enna and are available for selected topics

Program Delivery

Live Onsite

In Your Own Meeting Room

Live Onsite

Still The Best Way To Train

For most Lean topics, there is no substitute for a live instructor, interacting with your people discussing their issues and using examples and exercises from their own operations.

Our onsite programs range from half-day employee orientations to full-blown week-long Kaizen events. Many use our standard programs as a basis but incorporate actual exercises and projects from your facility. This type of workshop is especially good for many Lean topics that are counter-intuitive and require an actual experience to appreciate.

Online

Convenient & Effective for Selected Topics

Live Online

Convenient & Effective for Selected Topics

We offer online training in a live format for several topics that suit this medium. With our programs, your learning team meets in your conference room weekly for 1-2 hours. Our instructor joins online for discussion and presentation. The teams work on "homework" assignments between sessions. The homework includes exercises and a major project from their own operations.

With this format your people have time for reflection and internalization. They also have time to complete a Kaizen project that would not normally be feasible within the confines of training.

Public Programs

Public Programs

For Individual Learning

Public Programs

For Individual Learning

We have presented hundreds of public seminars in conjunction with program organizers. In recent years, most of these have been outside the U.S.

Our Instructors

Experienced—Knowledgeable—Authoritative

Your people will learn more, gain more practical knowledge and stay more engaged with Strategos instructors. Our instructors and program developers have extensive backgrounds in Adult Education as well as the specific topics. Most have learned their craft from pre-eminent seminar companies.

They have a vast store of anecdotes and examples from their industrial experience and often go "off script" to address specific issues raised in class. This requires experience and a confidence that is often missing in adult training.

Arrange A Workshop

Three Easy Steps

Unclear objectives, multiple constituencies and buzzwords can make for difficult training decisions. We try to make it easy—three basic steps start with a conversation...

|

|

Call us for an exploratory conversation. We will ask some basic questions about your situation, objectives and people. We will also discuss possible formats and content. |

|

|

Review our proposal. We will email a proposal in a day or so. It may be exactly what you want. Or, it may be a basis for further discussion between us or with your colleagues. If and when you are ready we... |

|

|

Set the dates. You can suggest some possible dates; we fit these with our upcoming schedule. We can usually find a mutually agreeable time within 2-6 weeks. |

Call us today at 816-931-1414 ( or send an email) to explore needs, options and costs. Then, you can decide if Strategos will be right for your people.

25+ Years of Lean Training

Workcell Design

Participants mockup their new workcell design on the seminar room floor. The teams developed viable cell designs for their electronic manufacturing operation.

--Guadalajara, Mexico

Worker Orientation

Factory workers get final instructions from Brian Rhodes before starting their Lean Simulation. This was part of a major change to cellular manufacturing.

--Texarkana, Texas, USA

Internalizing Lean Concepts

Workers prepare for a Lean simulation as part of their Lean Orientation workshop. This simulation is part of a half-day orientation for plant personnel.

--Texarkana, Texas, USA.

SMED Kaizen

Printing press operator practices the SMED procedures worked out by his team. Setup time was reduced by over 50% in a one-day session.

--Merced, California, USA

Large Scale 5-S Kaizen Event

A 5S team reports to management on the results of their two-day kaizen event. Seven teams and 46 people participated in this

workshop. The facility was an electronics plant with over 30,000 sf of clean room space. The organization discovered that "clean"

was not really clean and it was certainly not organized or efficient.

--Milpitas, California, USA

5-S Kaizen & Training

Shipping workers admire their 5S handiwork. This was one result of a one-day mini-kaizen that involved all production areas.

--Fremont, California, USA

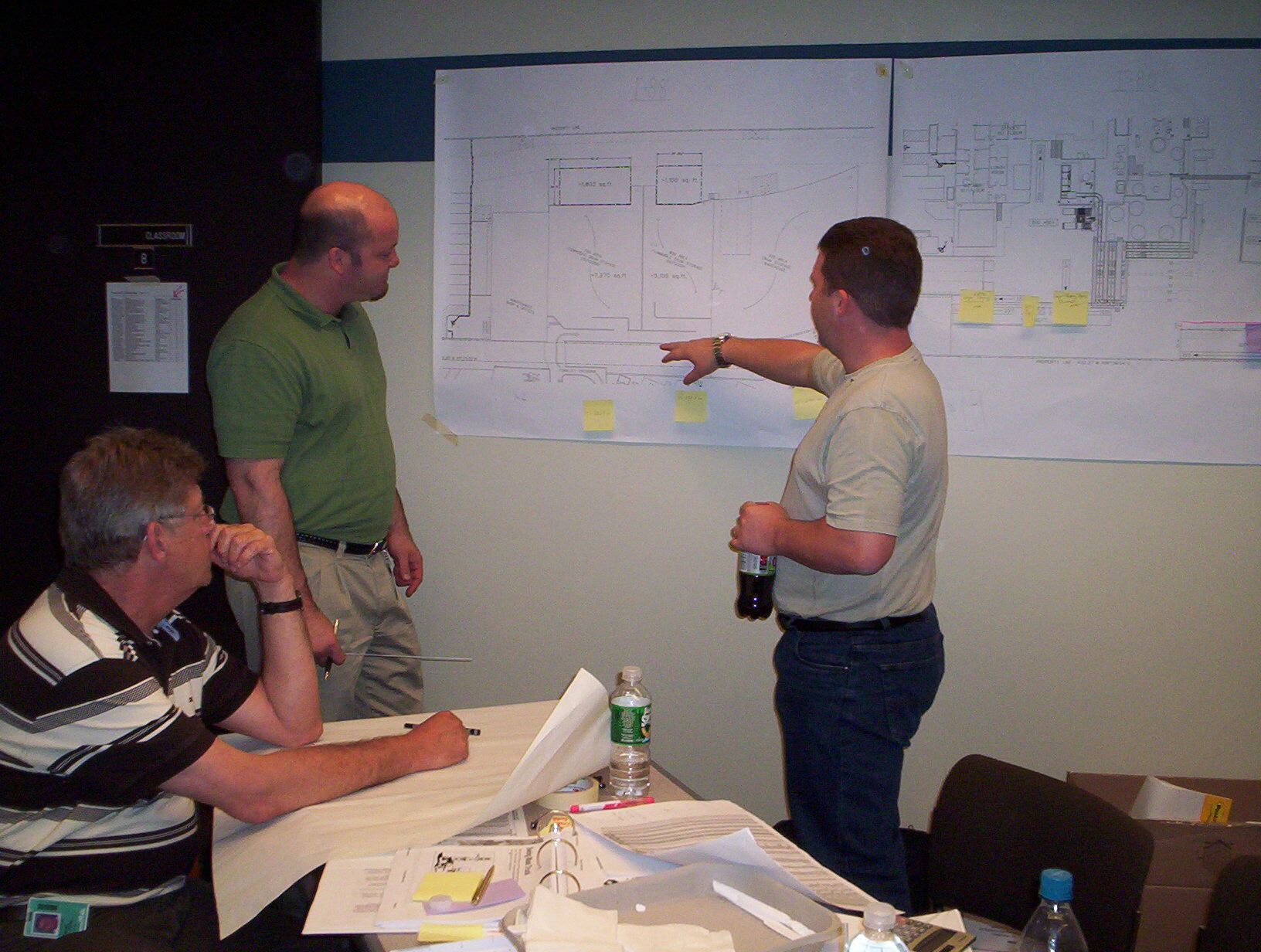

Facility Planning Kaizen/Training

This team is discussing their site plan for a new plant in China. A five-day facility planning workshop was combined with a kaizen event. The session raised important Manufacturing Strategy issues.

---Allentown, Pennsylvania, USA

VSM Exercise

Mr. Lee assists a team that is working through a Value Stream Mapping exercise. We try to minimize lecture and maximize applications in our seminars.

---Jakarta, Indonesia

Value Stream Mapping

Quarterman Lee leads a Value Stream Mapping seminar. Give and take discussion with the instructor and within the teams is an important feature in all of our programs.

---Shanghai, China

Lean Implementation-China

Participants in a Lean Implementation seminar, also in Shanghai. Mr. Lee is near the center. Chinese industry has been very aggressive at implementing Lean.

---Shanghai, China

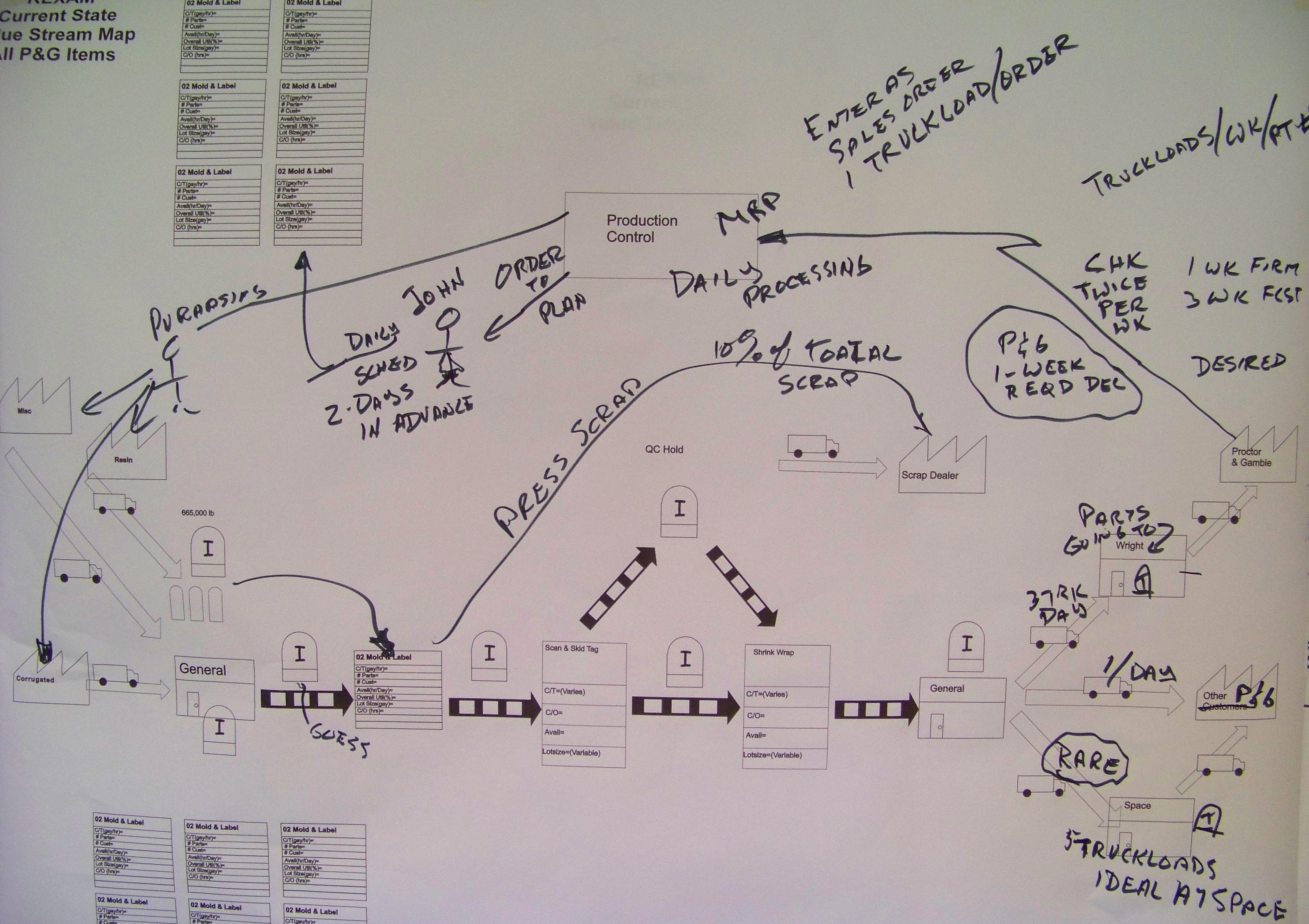

Supply Chain Kaizen

A kaizen team for a plastics injection molder developed this working version of their Extended Value Stream. Implementation will save several million dollars per year.

---Kansas City, Missouri, USA

International Supply Chains

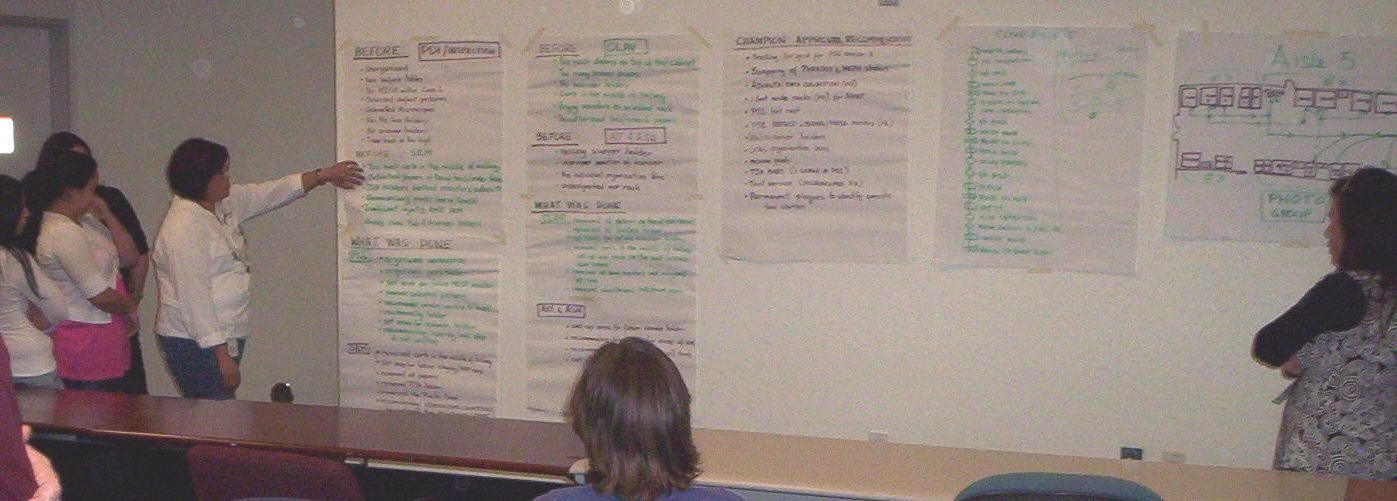

Instructor Lourdes Menendez discusses the extended value stream map developed by one team. in a three day supply chain kaizen . Border crossing made the situation especially challenging.

---Puebla, Mexico

Supply Chain Dynamics

Executives experience the dynamics of supply chains with the MIT Beer Game. Such dynamics are difficult to perceive in ordinary work experience.

--Stockholm, Sweden.

Lean Office Kaizen

This Kaizen event brought together 47 people from different functions and locations. The company's goal was faster installation speed for a new data service. The team identified changes that would reduce time from 12 weeks to three weeks and, possibly, to one week.

---Kansas City, Missouri, USA

■ ■ ■ ■ ■ ■ ■