Lean Supply Chains, Suppliers and Extended VSM

Lean Supply Chains

Extended Value Stream Mapping

Extended Value Stream Mapping and the development of a Lean Supplier network is the topic of this intensive, in-depth seminar. It starts with fundamental learning about supply chains using MIT's "Beer Game" and includes case study exercises from Toyota, Cisco and McDonalds. Participants explore the subtleties and nuances of a Lean Supplier network.

If your company is serious about suppliers, this is the program that can provide a deep understanding of fundamentals and tools for a long-term supplier strategy. It also includes an Extended Value Stream exercise taken from your own company.

Program Summary

| Format | Onsite Workshop | Who Should Attend? |

| Time | 3-Day |

Executives Managers Engineers QA Purchasing Production Schedulers |

| Cost | $6700 (Includes Travel) | |

| Participants | 5-35 | |

| Next Step | Call us at 816-931-1414 |

Participants Will Learn...

Why the opportunities to eliminate waste go far beyond the factory.

How variation in demand increases in upstream processes.

The causes and destructive effects of demand amplification.

Using kanban with overseas suppliers.

The science of Chaos and how chaotic effects create huge problems in the supply chain.

Toyota, McDonald's and the ideal extended value stream.

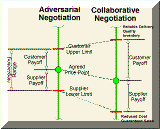

How lower prices can be advantageous for both the customer and supplier.

How to extend Value stream mapping throughout the supply chain and use it to improve performance.

Helping suppliers to streamline their operations, reduce price and deliver on time.

How to evaluate suppliers.

Vertical integration-- the pros and cons.

How to develop and execute a Lean Supplier Strategy.

How to analyze your own Extended Value Stream and streamline your supply chain.

Program Outline

1. Looking Beyond The Factory

2. "The Beer Game" Supply Chain Exercise

Classic simulation was developed at MIT demonstrates effects of time delays and insuficient information in an extended value stream.

3. Amplification of Demand

3.1. Jay Forrester & Industrial Dynamics

3.2. The Reasons for Demand Amplification

3.3. Reducing Amplification

4. Computer Simulation

4.1. The Situation At ABC Tractor

4.2. The simulation Model

4.3. Simulation Results

5. Chaos In Value Streams

5.1. Chaos Video

5.2. The Fundamental Causes of Chaos

5.3. Reducing Chaotic Effects

5.4. Chaos In Manufacturing

6. The Ideal Extended Value Stream

6.1. The Toyota Model

6.2. Open Book Relations

6.3. Shared Benefits & Savings

6.4. Shared Demand Information

6.5. Joint Process Design

6.6. Long-Term Relations

6.7. Video: Leaning The Supply Chain

7. Mapping The Extended Value Stream

7.1. The Mapping Team

7.2. Extended VSM Exercise

Create Current Value Stream Map for participant's product.

8. Future State Maps

8.1. Future States

8.2. Mapping The Future States (Exercise)

Create Future State VSM for your product.

9. Methods for Improving Suppliers

9.1. Selecting Lean Suppliers

9.2. Improving Suppliers

9.3. Creating New Suppliers

9.4. Exercise: Selecting Improvement Methods

10. Evaluating Suppliers

10.1. The Lean Assessment

10.2. Lean Assessment Exercise

10.3. Continuing Performance Evaluation

11. Vertical Integration Strategy

11.1. Michael Porter's Model

11.2. Vertical Integration Decisions

12. Implementing A Lean Supplier Strategy

12.1. How To Develop an Implementation Plan

12.2. How Long Will It Take?

12.3. Focusing On The Most Critical Suppliers

12.4. Class Project: Develop A Plan

Half-day project develops an implementation plan based on the client's actual situation.

■ ■ ■ ■ ■ ■ ■