Strategic Scheduling for Lean

Strategic Scheduling for Lean Manufacturing

In this seminar, participants design a Lean scheduling system for their own plant. They will integrate the six basic scheduling methods into a practical strategy for Lean Manufacturing. This is a unique offering that covers fundamental topics not found in the usual kanban or scheduling courses.

Program Summary

| Format | Onsite Workshop | Oline | Who Should Attend? |

| Time | 2-Day | 2-4 Wks |

Managers Engineers Materials Managers Schedulers Production Supervisors |

| Cost | $5700 (Includes Travel) | $4700 | |

| Participants | 5-40 | 5-20 | |

| Next Step | Call us at 816-931-1414 | ||

Participants Will Learn...

Some Basics

Lean Manufacturing and what it requires from scheduling.

How to clarify conflicting scheduling objectives.

To measure and track scheduling performance.

Inventory, Capacity, & Backlog

The role of inventory in Lean.

How scheduling can reduce the financial demands that inventory makes .

Why excess capacity can be profitable.

How to determine utilization goals.

Why capacity decisions are strategic and NOT financial.

Make-To-Stock, Make-To-Order, or Assemble-To-Order.

Forecasting

The limitations of forecasting and how to overcome them.

Guarding against forecasting surprises.

The Science Behind Scheduling

System Dynamics, Chaos & feedback.

Why systems go berserk from chaos, oscillation and instability.

Using Theory of Constraints.

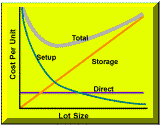

Rationalized Lot Sizing

How to calculate the best Lot Sizes.

Why small lots ease planning & reduce inventory.

Production Scheduling Methods

Six basic methods & where they apply:

|

Broadcast Kanban Period Batch Control |

Direct Link Re-Order Point (ROP) MRP/ERP |

-

How Kanban simplifies MRP and improves performance.

-

Simplify, streamline & integrate MRP.

Developing Your Strategy

-

How to select the optimum method for each process and each product group.

-

About integrating various methods into a comprehensive scheduling strategy.

-

The implementation action plan.

Program Outline

1. Introduction

What Is Scheduling?

Identify Your Objectives

How To Measure Performance

2. Forecasting

The Components of A Forecast

Forecasting Methods

How Good Is Your Forecast?

3. Inventory, Capacity & Backlog

Inventory Record Accuracy

The Role of Inventory

Capacity

How To Measure & Define Capacity

What Capacity Should You Provide?

What Is Backlog?

Backlog, Inventory, & Capacity

Make-To-Stock, Make-To-Order, or Assemble-To-Order?

4. Lot Sizing

What Lot Size Should You make?

How Lot Size Affects Scheduling & Inventory

5. Theory of Constraints (TOC)

Marching Exercise

The Corrupting Effects of Variability

How To Apply TOC

6. The Dynamics of Production Systems

The Beer Game: Instability & Chaos

7. Six Production Control Methods

What Is Kanban?

Exercise: Operating A Kanban System

How To Design A Kanban System

Re-Order Point (ROP, Min-Max)

Materials Resource Planning (MRP/ERP)

How Does MRP/ERP Work?

The Hazards of MRP/ERP

How To Make MRP More Effective

Integrating MRP/ERP With Other Methods

8. Putting It Together

Developing Your Strategy

The Hierarchy of Methods

■ ■ ■ ■ ■ ■ ■