Kanban For The Job Shop

Adapting Kanban for Low-Volume & High Variety

Kanban is a system that controls flow of work through a multi-stage process. The classical version of kanban, as developed at Toyota, is normally used for repetitive production. However, some of the benefits of kanban can be attained even in a job shop environment where low volumes and high variety dominate.

In a job shop, kanban will prevent work from accumulating excessively at any particular workstation and distribute labor resources evenly. By glancing at their input queue, operators know what needs to be done at their workstation and request help when necessary. Correspondingly, operators whose queue goes empty can immediately move to stations that may require help. This relieves supervisors of significant coordination tasks and allows them to focus on exceptions, special situations and technical problems.

While the principles of job shop kanban are essentially the same as for repetitive production, the applications are less obvious and may require more imagination. The possibilities are endless.

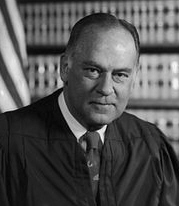

"I know it when I see it."

Potter Stewart, Associate Justice of the Supreme Court

About Job Shops

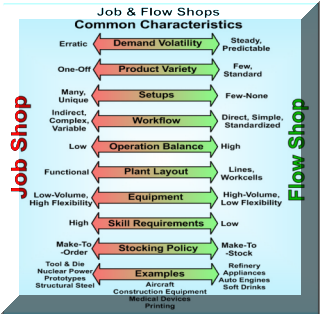

Job shops are difficult to define, although we usually know a job shop when we see it. Part of the problem is there are very few pure job shops or pure flow shops. Most production shops lie on a spectrum between two extremes. In addition there are multiple dimensions or characteristics and a particular shop may look like a flow shop in product variety, for example, but more like a job shop in its plant layout.

CNC and other new technology has also blurred the traditional concepts of job shop and flow shop. On the job shop end of the spectrum, technology combines multiple operation types on one or two machines this reduces setup and changeover time. It also simplifies routings.

On the flow shop end, technology allows more variety on a single flow line. This increases the physical or customer-perceived variety available without increasing workflow and manufacturing complexity.

The figure shows some of the most common characteristics of job shops and flow shops along with examples typically found at each end of the spectrum as well as the middle.

The Essence of Kanban

For job shops, it helps to think first about the essence of a kanban system and ignore the peripheral paraphernalia such as cards, boards and containers.

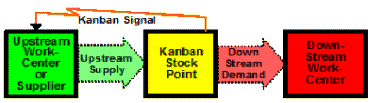

Kanban takes place between two workcenters; an upstream supplier and a downstream user. It applies to a single part or SKU. Between the workcenters, a Stockpoint holds a (relatively) small stock. A signal immediately notifies the upstream workcenter of changes in stock status.

For our purposes here, we can define a Kanban system as one that has:

-

1. Small Stock Available

-

2. Withdrawal Signal With Immediate Feedback

-

3. Fast Replenishment, Small Quantities

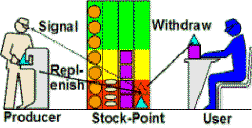

This figure illustrates with a block diagram and simple example. In this example the operator at the upstream workcenter simply watches the Stockpoint and, with the aid of color codes, determines what he produces next. This is a simple, visual signal that is highly effective. There are many other types of signals such as cards, lights and even colored golf balls.

The Rules of Kanban

Kanban requires a set of rules and procedures and the discipline to carry them out. A simple system, as in such as in the figure, needs only two basic rules:

-

No production without a kanban signal.

-

Do not arbitrarily change authorized stock levels.

More complex systems using containers or cards may have additional rules. For the system in the previous figure, the “User” or downstream workcenter, simply builds what its customer needs immediately removing required items from the Stockpoint. The “Producer” or upstream workcenter observes the Stockpoint and decides which items to build based on the stock level. Colored zones make the stock status more obvious:

-

Red zone means “make this part NOW.”

-

Yellow zone means “be prepared to make this part soon.”

-

Green means “you may build this part if convenient but only up to the maximum level.”

Enhancement Characteristics

Many kanban systems have characteristics that enhance their operation but are not fundamental. The greater these characteristics, the better it works but they are not essential to the operation. Some common enhancement characteristics are:

Fast Setups/Small Lots

Fast Replenishment/Small Replenishment Quantities

Small Transfer/Handling Lots

Job Shop Kanban

Production Unit

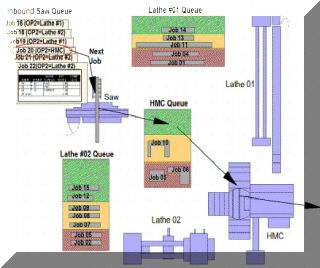

We normally visualize the production unit as a single physical item, e.g. a shaft, casting, subassembly, etc. However, in a job shop we may find it useful to think of a production unit as an order or work order. Such an order may contain several items in a batch but is usually processed as a batch. When orders tend to be fairly consistent in their work time the kanban stockpoint is calibrated in "number of orders". In the example below the Lathe #01 queue is allowed a maximum of six jobs. If jobs vary greatly in work time, it might be best to calibrate the queues in terms of work hours. A queue might have a maximum of 16.0 work hours whether this consists of 16 1.0-hour jobs or two 8.0-hour jobs.

Another modification involves the way queues are identified. In traditional kanban, queues are identified by part number. For job shop kanban, we identify queues by the next operation identifier, e.g. Lathe #01, Lathe #02, etc.

Repetitive Components

Many semi-job shops use common components on multiple and repetitive jobs. Whether these components are purchased or fabricated they are an excellent opportunity for kanban to mitigate BOM errors, kitting labor and a host of other issues associated with MRP/ERP.

Common Operations

When a single workstation feeds multiple downstream workstations there is a good opportunity for kanban control.

Internally to Workcells

The figure below shows a workcell arrangement where a single saw feeds three separate machines that complete the process. With a more traditional, sequential workcells the queues between operations are usually quite small. Kanban can work well to balance equipment in such cells even in a job shop.

Integrating with MRP/ERP

Questions may arise about the integration of kanban with MRP/ERP systems. The "parallel universe" approach is helpful. Here we allow the MRP/ERP system to operate normally for purposes of capacity planning and inventory valuation. The shop floor, however, operates with the kanban system and mostly ignores the MRP/ERP system. The two systems do need a periodic reconciliation after a monthly or yearly physical inventory. Backflushing is another method and phantom assemblies can be helpful in some situations.

Example #1

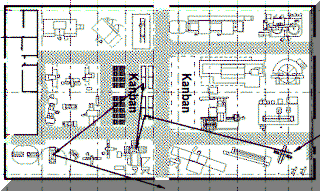

Common Operations & Intra-Workcell

The figure at right also shows an upstream workcenter, the bandsaw in this example, and several possible downstream workcenters. Each workcenter has an input queue. This input queue might be a shelf, a pallet rack or simply a space marked on the floor. A job consists of the item(s) being processed and an accompanying work order or routing sheet.

-

1. The bandsaw performs the first operation (OP1) on each job. The bandsaw operator completes work on that job and delivers it to the input queue for the next operation (OP2). The input queue for OP2 may contain several other jobs delivered either from the bandsaw or from other operations. The bandsaw operator notes how many other jobs are in this queue.

-

2. The bandsaw operator returns to his own workstation and selects his next job from the bandsaw input queue. The job he selects should be a job whose next operation has few jobs in its queue. If all the possible downstream queues are full, the bandsaw operator stops processing new jobs and moves to assist another workcenter. The bandsaw operator may also have information that certain jobs have high priority and this can modify his decision about which job comes next.

-

3. Operators at each subsequent operation use a similar process to determine their sequence of work. The transfer of jobs from upstream to downstream stations may be done individually or an operator may accumulate several jobs before stopping work to deliver them. It may also be useful to have a dedicated material handler who makes a regular circuit picking up and delivering jobs.

In this example, assume the queue status is as shown. The saw operator must choose his next job from the various jobs available in his input queue. He should NOT choose any job that will go to Lathe #1 as the subsequent operation because the queue at Lathe #1 is full. There would be no place to put a job for Lathe #1 and Lathe #1 has plenty of work available. If the operator were to choose Job 16, the next job in the queue, it would only occupy floor space and increase Work-In-Process.

Lathe #2 and the HMC both have work available to them and both have queue space for an additional job. However, the queue for HMC is lower than the queue for Lathe #2 so the operator should choose the next job in line for the HMC. This is Job 20.

In this figure the best location for the stockpoint is at the saw and operators go to the stockpoint when the need their next job. All of this equipment might be placed together in a workcell as shown. Or it might be in a more distant location.

Example #2

Shop-Wide Kanban Example

Here we see a shop-wide kanban stockpoint and show the movement of a particular order that visits three workcenters. The order resides briefly in the stockpoint area between operations. This arrangement introduces more complexity and more travel compared to the previous example but retains most of the benefits in reduced inventory and better daily scheduling.

It may appropriate when equipment cannot be moved together or when there is too much variety in the routings.

■ ■ ■ ■ ■ ■ ■

|

The Strategos Guide To Value Stream and Process Mapping goes beyond symbols and arrows. In over 163 pages it tells the reader how to do it and what to do with it. |

|

PUB FEB 2016 |

|

|