Aisle Design

Principles & Procedures for Working Facilities

1. Don't Pave the Cowpath!

A rationalized aisle system is essential for the movement of people, information and product; it is the circulatory system of most workplaces. It improves flexibility for the inevitable future changes and rearrangements. It improves communication by making the process and people visible and clear. Aisle system design is inherent to and concurrent with the design of a macro layout. While most plant layouts are drawn with CAD, the complexity induced by the concurrency of handling and layout requires a mostly human process. This is especially true for existing facilities where it is impractical to change many existing features.

Almost all attempts to rationalize, systematize or computerize space planning are variations of Muther’s Systematic Layout Planning (SLP)[4] procedure. The particular step in SLP that has been most resistant to further efforts is the generation of a macro (block) layout based on the layout primitive (space-relationship diagram) and constraints (modifying factors). Most attempts to computerize this step produce crude outputs that require considerable manual manipulation.

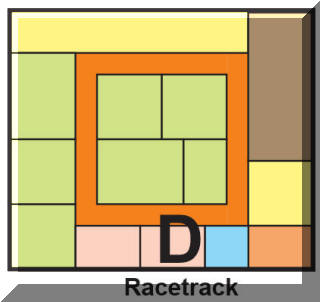

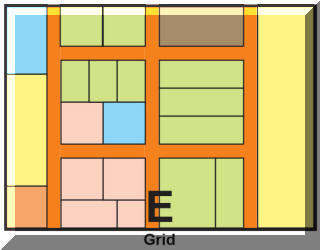

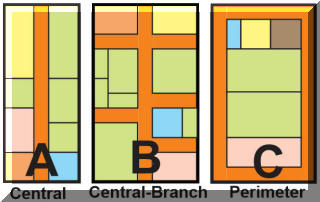

Figure 1-A,B,C Aisle System Concepts

2. Aisle System Concepts

In many facilities there is little order or pattern to the aisle system. Indeed, the aisle layout would suggest a bovine origin rather than an engineered design. Figure 1 offers five conceptual aisle systems. One, another or a combination will usually adapt to most spaceplans.

Central aisle systems (Figure 1-A) work well with long narrow buildings. These are often seen in mill-type buildings with overhead cranes. When the building has a bit more width, aisles may branch out from the central aisle as in Figure 1-B. The Central-Branch concept is often seen in warehousing where traffic is light. Perimeter aisles (Figure 1-C) waste space, as noted previously. However a perimeter system may be appropriate where there are long processing lines such as with bolt-makers, assembly lines and bottling lines; it depends on the proportions.

Racetrack systems work well in medium-size buildings as in Figure 1-D. They are probably the most versatile of aisle configurations. Large and, especially very large factories will generally use a grid system similar to Figure 1-E. Very large facilities might also use different configurations in different parts of the plant.

![]()

This web page is abbreviated from a paper Mr. Lee presented at the Institute of Industrial & Systems Engineers Annual Conference, June, 2020. Click below to download a pdf copy of the complete paper.

3. Guidelines for Aisles

Below are several general guidelines for aisles. These are not absolute rules and they are often compromised by other factors. Moreover, while such guidelines are helpful they give no insight for a design procedure or the mental processes required. The downloadable article explains such a procedure.

3.1 General

- Every SPU (Space Planning Unit, Activity Area, department) should be adjacent on at least one side to a main aisle.

- Aisles adjacent to building walls waste space because they serve SPUs on only one of their sides.

- Perimeter aisles provide flexibility and good traffic flow similar to perimeter highways around a city. However, they waste space since an aisle against a wall requires the same width as an aisle between SPUs but only serves SPUs on one of its two sides.

- Racetrack or Semi-perimeter aisles have the advantages of perimeter aisles but use space more efficiently.

- Aisles should be as straight as practical with the fewest turns and intersections.

- Avoid placing columns within an aisle, particularly if there is heavy equipment traffic such as fork trucks.

- Aisles adjacent to columns are desirable since they minimize the number of columns within an SPU. This offers greater flexibility for layout within the SPU.

- Dead-end aisles are suitable only for occasional traffic and unsuitable for trailers.

- One-Way aisles are narrower than two-way aisles but should be spaced close enough to avoid long detours.

- Chamfered aisles at intersections make turning easier, increase visibility and may allow smaller aisle width.

3.2 Space

- Main aisles for manufacturing usually occupy 20%-35% of total space but this is highly variable.

- In a warehouse the size and space for aisles is even more variable than for manufacturing. It depends mostly on the storage and handling equipment.

- Functional layouts are likely to require more internal aisle space then cellular layouts.

3.3 Aisle Width

- Industrial material handling aisles should be at least 4 feet wide and at least 3 feet wider than the largest equipment that has to pass through them.

- One-way transit-only aisles should be at least one foot wider than the widest load and two-way aisles should be three feet wider than the widest normal combined passing loads. These are minimums for occasional traffic and short distances only.

- Aisles accessing storage locations may need additional width for fork truck maneuvering.

- Pedestrian-only aisles should be at least 28” wide for occasional traffic. For heavier traffic, 4-6 feet is preferred. Refer to local building code for evacuation requirements.

- In the absence of load and equipment information, Figure 2 is a general guide for forklift aisles.

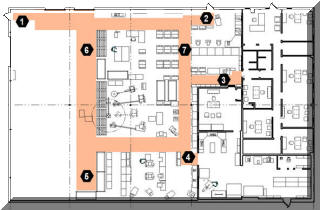

Aisle design seems to be a mostly an exercise in compromise and few designs meet all the guidelines enumerated earlier. This particular spaceplan (Figure 3) is no exception. The number flags on Figure 3 explain some of these compromises:

(1) This narrow aisle is for emergency evacuation only.

(2 & 3) Pedestrian aisle only. Not worth relocating a door to keep this aisle straight.

(4) Not worth relocating a door to keep this aisle straight.

(5) This is a dead-end aisle but it is rarely used since SPU#12 is for long-term die storage.

(6) This main aisle is only eight feet wide but that is sufficient for the single walkie fork truck that is utilized.

(7) This aisle is only 5’ wide because handling is with tote boxes on a stock cart.

7. Summary

This paper attempts to bring a degree of rationality and procedure to the subject of aisle and macro-layout design. However, it remains a somewhat messy business, highly dependent on experience and individual insight. There may be situations where the logic presented is inadequate or does not apply but from the author’s experience, this is a good way to start. You may download the complete paper as presented at the 2020 IISE Conference.

References

References

[1] Apple, James M., (1991), Plant Layout & Material Handling, 3rd Ed., Krieger Publishing, Malabar, FL, USA.

[2] Klausnitzer, A. and Lasch, R., (2019), Optimal Facility Layout and Material Handling Network Design, Computers and Operations Research, Elsevier.

[3] Lee, Q., (1996), Facilities and Workplace Design, Engineering & Management Press, Norcross, GA, USA.

[4] Muther, R., and Hales, Lee, (2015), Systematic Layout Planning, Management & Industrial Research Publications, Marietta, GA, USA.

[5] Meyers, Fred E., (1993), Plant Layout and Material Handling, Prentice-Hall, Englewood Cliffs, NJ.

[6] Phillips, Edward J., (1997), Manufacturing Plant Layout, Society of Manufacturing Engineers, Dearborn, MI.

■ ■ ■ ■ ■ ■ ■