Onsite SMED Kaizen Event

Setup Reduction (SMED) Kaizen Event

Two Days to Faster Setups

This intensive two-day Setup-Reduction

Kaizen Event (blitz) generates order-of-magnitude improvements in setup time and setup cost. The

immediacy and urgency of this session changes paradigms, generates enthusiasm and brings rapid, low-cost

solutions.

This intensive two-day Setup-Reduction

Kaizen Event (blitz) generates order-of-magnitude improvements in setup time and setup cost. The

immediacy and urgency of this session changes paradigms, generates enthusiasm and brings rapid, low-cost

solutions.

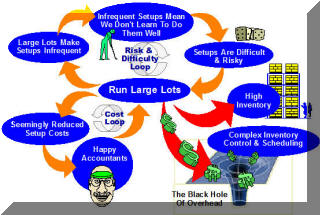

Setup Reduction or SMED is the key to small batches, fast response, quality, and Kanban production control in many situations.

Program Summary

| Format | Onsite Workshop | Who Should Attend? |

| Time | 2-Day |

Setup Operators Production Operators Supervisors Engineers Schedulers Managers |

| Cost | $5500 (Includes Travel) | |

| Participants | 5-16 | |

| Next Step | Call us at 816-931-1414 |

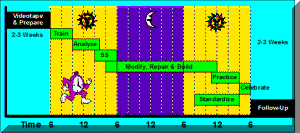

Videotape & Prepare-Strategos helps identify a setup and client videotapes it. Preparations are made and resources such as Maintenance, Engineering and Tool Room are reserved. Team members are assigned.

Train- Four hours of training prepares the teams with tools and techniques for analysis.

Analyze- Teams analyze videotapes and plan improvements.

5-S- Teams execute 5-S techniques to clean, paint, arrange and organize the equipment and the area.

Modify, Repair & Build- Repairs and changes to equipment and tooling are made. Fixtures, racks and carts are built. Maintenance and Tool Room personnel may work into the night.

Practice- Teams practice setups & videotape improvements.

Standardize- Some team members practice; others document the setup.

Follow-Up- Some improvements must be left for later. These are documented. Your Strategos advisor continues support via phone and email.

Participants Will Learn...

-

About Five dramatic benefits from SMED.

-

A structured Four-Step process for streamlining changeovers.

-

Dozens of specific ideas to improve setups.

-

How to overcoming the deadly effect of poor housekeeping.

-

How to eliminate adjustments--the most time-consuming and frustrating part of setup.

-

Using teams to changeover large, complex equipment.

Program Outline

1. The Importance of Setup Reduction

Optimum Lot Sizing

Consistency

2. The Four Phases

Organization, Maintenance & Housekeeping

Converting Internal Elements To External

Improving Elements

Eliminating Adjustments

3. Documenting Current Practice

Using Videotape

Process Charting & Multi-Task Charting

4. Improving The Setup

Specific Techniques for Various Industries

Brainstorming

Analyzing The Tapes & Charts

5. Implementing Your Program

Establishing Metrics

Setting Priorities

Training

■ ■ ■ ■ ■ ■ ■