5S Workshop & Mini-Kaizen

5S for Work Teams

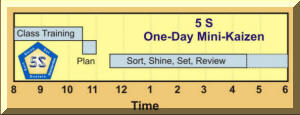

Stage I Seminar & Mini-Kaizen Event

In this program, work teams learn the principles of Five-S and put them into practice in their own workspace. This program combines classroom training with a mini Kaizen Event to make the transition from classroom to practice.

The program is a great start for individual teams. While the time allowed is very short, it is surprising how much gets accomplished with an experienced Strategos facilitator and a bias for action.

Program Summary

| Format | Onsite Workshop | Who Should Attend? |

| Time | 1-Day |

Work Teams Support Personnel |

| Cost | $3600 (Includes Travel) | |

| Participants | 5-50 | |

| Next Step | Call us at 816-931-1414 |

Participants Will Learn...

-

How 5S improves the workplace.

-

Why 5S makes for easier tasks.

-

How to sort out the junk and avoid the "packrat" syndrome.

-

Using the Red Tags to eliminate junk.

-

Finding the optimum location for each item.

-

About standardizing work to avoid errors.

-

"How clean is clean?" and why Mother was right.

-

How to evaluate a workplace.

-

Photos and Mapping For Efficiency

-

How to keep from backsliding.

Program Outline

1. Introduction 5S and Visual Control

What It Is (and what it isn't)

Benefits of Implementing 5S

Purpose & Origins of 5S

2. The 5S' Sort, Set, Shine, Standardize & Sustain

Sort

The 3 Basic Categories

Red-Green-Yellow Tags

Shine

Examples - Before and After

Some Techniques to Use

Set-in-Order

Location, Boundaries & Recoil

3. Visual Control What Is Visual Control?

Signs, Signals, Controls and when to use each.

Visual Control Video

4.0 Into Practice

Planning The Kaizen Event

Re-Organizing The Workplace

Report on Results

5.0 Planning The Next Steps

Developing Your Project List

Setting Up The Daily & Weekly Schedules

7.0 Summary & Close

■ ■ ■ ■ ■ ■ ■