Socio-Technical Design

Principles & Guidelines

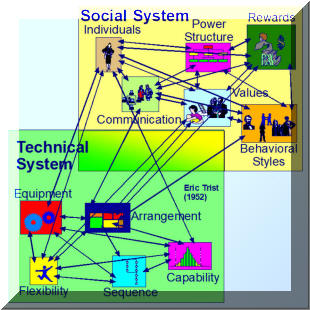

What Is A Socio-Technical System?

In the

early 1950's Eric Trist and the Tavistock Institute studied the English coal mining industry

where mechanization had actually decreased worker productivity. Trist proposed that

manufacturing (and many other) systems have both technical and human/social aspects that are

tightly bound and interconnected. Moreover,

it is the interconnections more than individual

elements that determine system performance.

In the

early 1950's Eric Trist and the Tavistock Institute studied the English coal mining industry

where mechanization had actually decreased worker productivity. Trist proposed that

manufacturing (and many other) systems have both technical and human/social aspects that are

tightly bound and interconnected. Moreover,

it is the interconnections more than individual

elements that determine system performance.

The technical system includes machinery, processes, procedures and a physical arrangement. We usually think of a factory in terms of its technical system.

The social system includes people and their habitual attitudes, values, behavioral styles and relationships. It includes the reward system. It is the formal power structure as depicted on organization charts and the informal power structure deriving from knowledge and personal influence.

Mechanization In The English Coal Mines

In the coalmines, mechanization had broken up tightly knit teams that had previously performed the entire extraction process from blasting to hauling to sorting.

-

With mechanization, different people performed the various steps of extraction on different shifts and this caused coordination problems.

-

The equipment was so loud people could not communicate and this inhibited teamwork and team development.

-

The pay system went from a group incentive system to an hourly wage system and this destroyed monetary motivation.

-

People felt alone, isolated, and unappreciated deep in the earth. This destroyed the powerful intrinsic motivators of pride, satisfaction and belonging.

The overall result for the English mining industry was decreased productivity and labor strife.

Principles of Socio-Technical Systems Design

1.0 Social System

1.1 There is no optimum organization. As the environment, culture, people and technology change, so should the organization.

1.2 When selecting people for a workgroup, strive for homogeneity in backgrounds and work attitudes.

1.3 Reduce wide variations in knowledge levels and variety through cross training.

1.4 Achieve High performance through commitment rather than compliance; more carrot than stick.

1.5 Build commitment by involving people in the shaping of their future.

1.6 Provide opportunities to satisfy unfulfilled higher order needs. (intrinsic motivators)

1.7 Adults learn primarily through experience. Integrate learning on the job through advisors, facilitators, and guided application.

1.8 Maintain ability for normal conversation between members at their workstations with compact layouts and noise control.

2.0 Technical System

2.1 Control variances at their source.

2.2 Ensure that the detection of a variance and the source of that variance occur in the same group.

2.3 Maintain quality by detecting variances in the process rather than in the final product.

2.4 Monitor inputs as carefully as outputs.

2.5 Size work buffers large enough to allow problem solving but small enough to prevent problem avoidance.

2.6 Match technological flexibility with the product mix.

2.7 Match technology scale with production volume.

3.0 Integration

3.1 Design the Socio and Technical systems simultaneously and jointly.

3.2 Give workers larger and more varied tasks and increase cycle time.

3.3 Integrate support functions within work groups to the largest possible extent.

3.4 Optimize the system rather than the system's components.

3.5 Begin and end a work group's technical boundary at a discontinuity in the material transformation process.

4.0 Managing The System

4.1 Allow teams to manage the daily work.

4.2 Coach and facilitate rather than supervise.

4.3 Coaches should manage the team boundaries.

4.4 Upper management should set goals, supply resources and manage the culture.

Al, at the wheel, his face purposeful, his whole body listening to the car, his restless eyes jumping from the road to the instrument panel. Al was one with his engine, every nerve listening for weaknesses, for the thumps or squeals, hums and chatterings that indicate a change that may cause a breakdown. He had become the soul of the car.

--John Steinbeck, "The Grapes of Wrath"

■ ■ ■ ■ ■ ■ ■